Predictive Health Monitoring of Railway Platform Doors

Industry

Electric railway transportation systems

Asset

Railway platform doors

Goal

Develop a software solution to monitor the health of railway platform doors and diagnose degradation

Impact

Established six key degradation events in just the first three months of the analysis project, prioritizing scheduled maintenance and saving manpower, resources and labor costs.

Overview

A Japanese-based global leader in electrical and electronic product manufacturing, with applications that range from transportation and air conditioning systems to automobiles and motorsport vehicles, was looking to monitor the health of their railway platform doors and improve their preventative maintenance schedule.

Solution

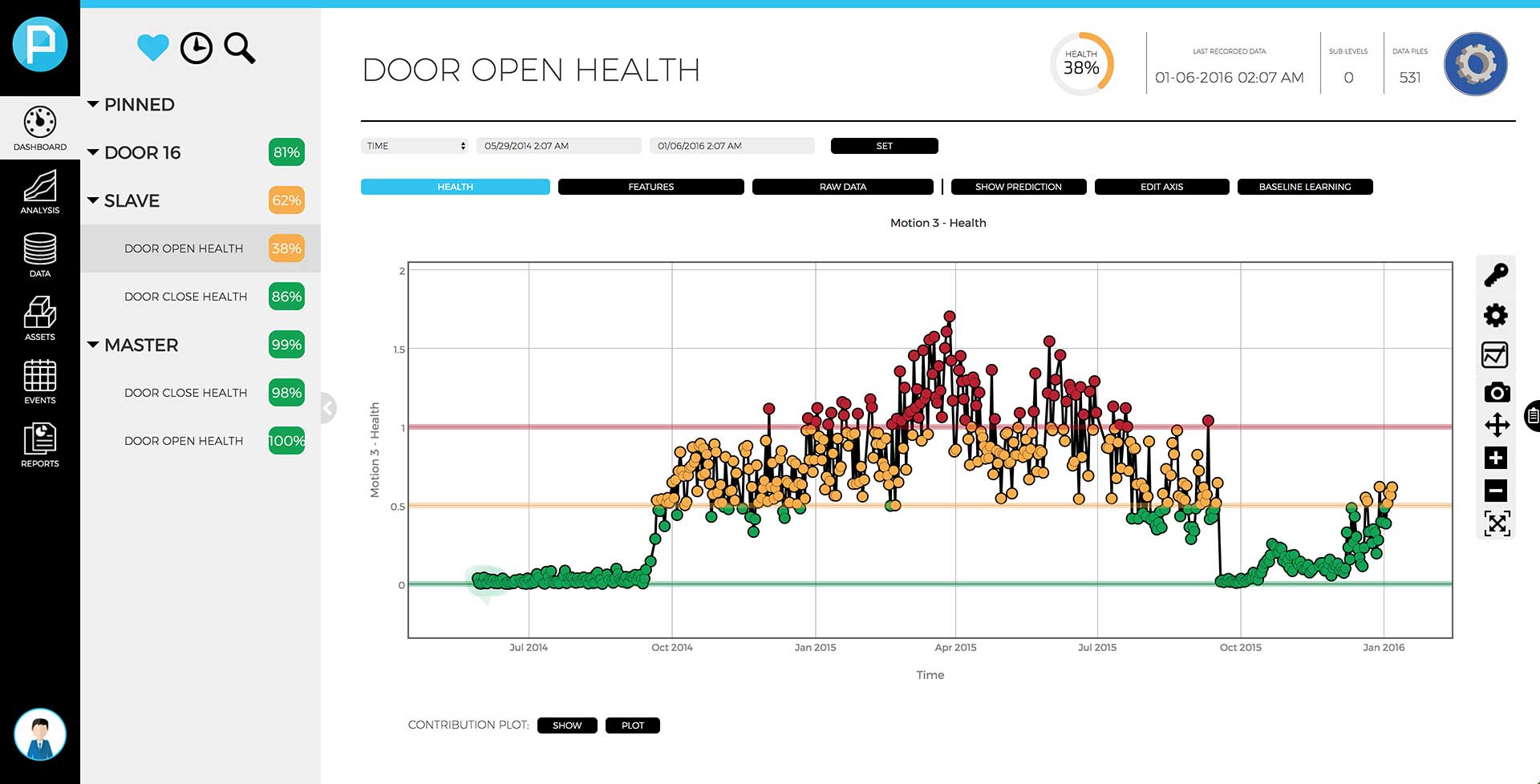

Initially, a data quality check was conducted in order to ensure clean, pre-processed data and more accurate prediction models. Predictronics then created a baseline health index. This gave our team a better understanding of the normal health of the railway doors within the transportation system. The baseline index was then compared to the current health data of the door and degradation patterns were established through magnitude-based and correlation indicators. This solution by Predictronics combined the evaluation of sensor measurements and health values from specific events, such as torque, lubrication, solenoid exchange and shoe adjustment, and developed health prediction models by comparing each specific faulty door to the other doors in that particular grouping. This method was a good approach since it does not assume that any time period is the baseline and compares doors with the same stroke length to each other.

Value

By using the developed prediction models, six key degradation events became apparent, including solenoid exchange issues, lubrication and shoe adjustment problems, and faulty stroke length between the doors. Predictronics noticed a significant change in torque trend waveforms when event health values would fluctuate. The final data-driven solution allows the company to prioritize their maintenance schedule, saving them wasted time, manpower, resources and labor costs. The theory that faults are directly related to torque can also be further validated over time with additional fine-tuning and maintenance record analysis.