Successful Deployments Of Predictive Solutions in the Cargo and Freight Industry

Part III: Air

Industry

Freight and cargo

Asset

Aircraft

Goal

Deploy predictive solutions for early detection and diagnosis of component failure in transport and cargo handling aircraft

Impact

Predicting and preventing component failures is the key to ensuring reliability and availability of aircraft that are critical to the on-time delivery of goods, resulting in reduced costs associated with unnecessary repairs, unplanned downtime, and delayed shipment schedules

Overview

While aircraft vessels are one of the lesser-used modes of freight transport, aircraft shipments are mostly known for their value, containing time-sensitive and precious cargo. One big example of this is the mail service, which frequently ends up on passenger planes due to its time sensitivity and its quick turnaround schedule. Common aviation issues stem from engine troubles, as well as defective gauges and instruments, which measure speed, fuel supply, and power.

Solution

In air cargo transportation, there are numerous assets within the aircraft which can experience failure. By utilizing historical records, such as from on-board sensors, maintenance logs, and flight recorder black boxes, Predictronics’ industry-experienced data scientists have created many custom predictive maintenance solutions for these mechanical systems and components, improving diagnosis accuracy and mean time to repair.

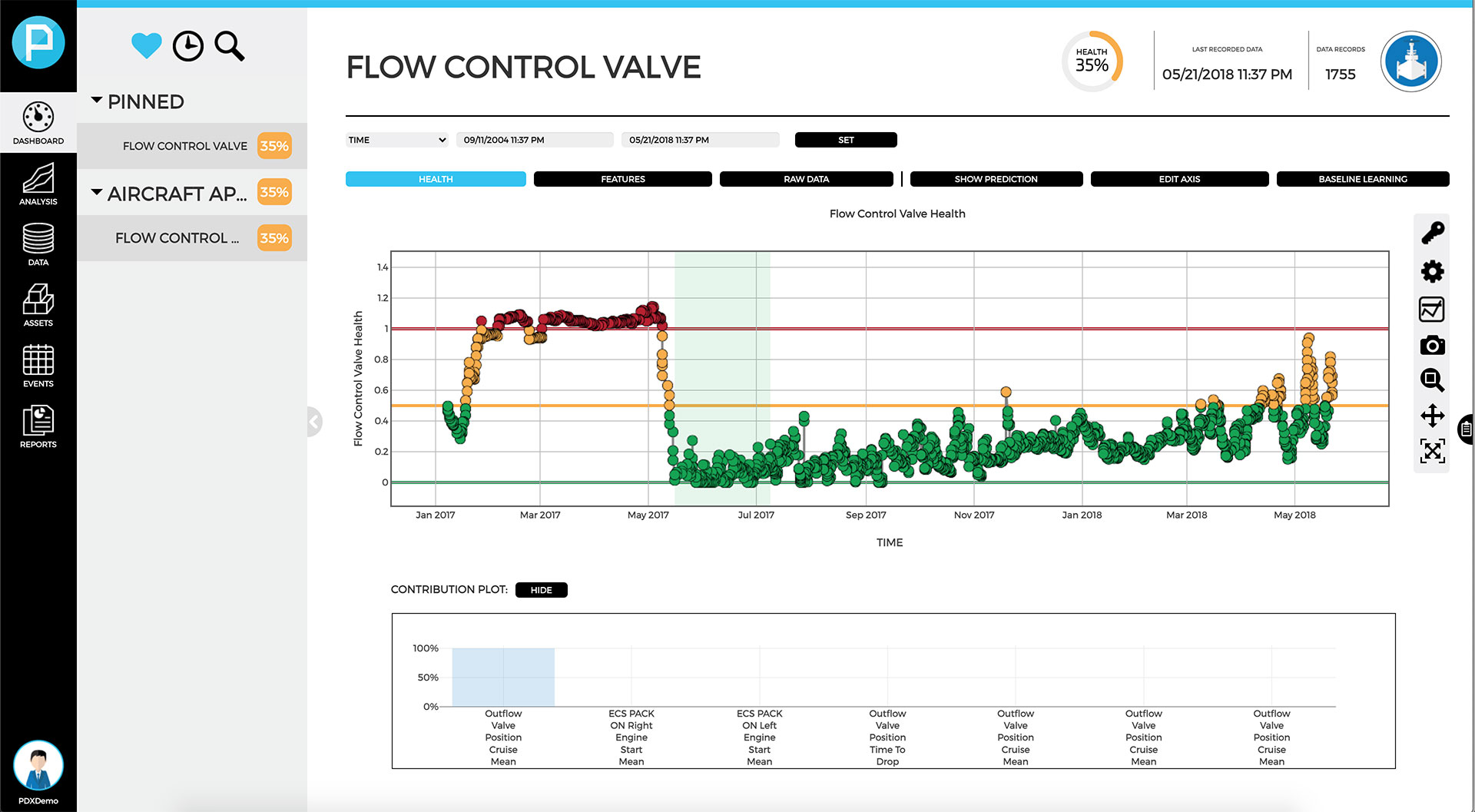

Predictronics delivered a predictive maintenance solution, powered by our PDX software, for a commercial aircraft customer. The solution provides early detection of failure in flow control valves, which are critical components in many aircraft systems.

This particular solution was able to predict two flow control valve failures several months in advance, allowing the customer to prioritize maintenance planning decisions and fix future valve issues before they occur, which can potentially cost the customer an estimated $74.20 per minute.

Value

According to PWC, nearly 30% of delays experienced by aviation companies are due to unplanned maintenance. Data-driven solutions provide airlines with the evidence they need to prioritize maintenance planning decisions and fix issues before they occur, increasing crew safety, reducing unnecessary costs and waste due to time-based and incident-based maintenance, and preventing delays in order to optimize freight delivery schedules.