Successful Deployments Of Predictive Solutions in the Cargo and Freight Industry

Part I: Land

Industry

Freight and cargo

Asset

Semi-trucks and railway

Goal

Deploy predictive solutions for early detection and diagnosis of component failure in transport and cargo handling vehicles

Impact

Predicting and preventing component failures is the key to ensuring reliability and availability of vehicles that are critical to the on-time delivery of goods, resulting in reduced costs associated with unnecessary repairs, unplanned downtime, and delayed shipment schedules

Overview

Semi-trucks are the most prevalent method of transport in the U.S. for freight and their efficiency, availability, and reliability are essential to the industry, as well as the nation’s economy as a whole. However, these semi-trucks face many common mechanical issues that can put them out of commission, from oil leaks and alternator issues to engine and transmission problems. The American Transportation Research Institute estimates the overall truck repair and maintenance costs per mile have increased by 66% in the last decade.

Rail transport is the second most-used mode of transportation in North America and is unique in that numerous industries count on the reliability and availability of rail freight. While trucks often deal in time sensitive deliveries, according the Federal Railroad Administration nearly 91% of the goods hauled by freight trains are bulk commodities, such as agriculture goods, energy products, automobiles and their components, construction materials, chemicals, food, raw materials, and heavy freight. Railways often see major wear-and-tear, leading to lubrication issues, as well as problems which stem from rolling contact fatigue (RCF), such as cracking, spalling, and shelling.

Solution

Within land freight transportation, semi-trucks and numerous railway assets can experience failure. These modes of transport share many common components, from diesel engines and transmissions to pumps and valves. By utilizing historical records, such as on-board vehicle sensors and maintenance logs, Predictronics’ industry-experienced data scientists have created many custom predictive maintenance solutions for these mechanical systems and components, improving diagnosis accuracy and mean time to repair.

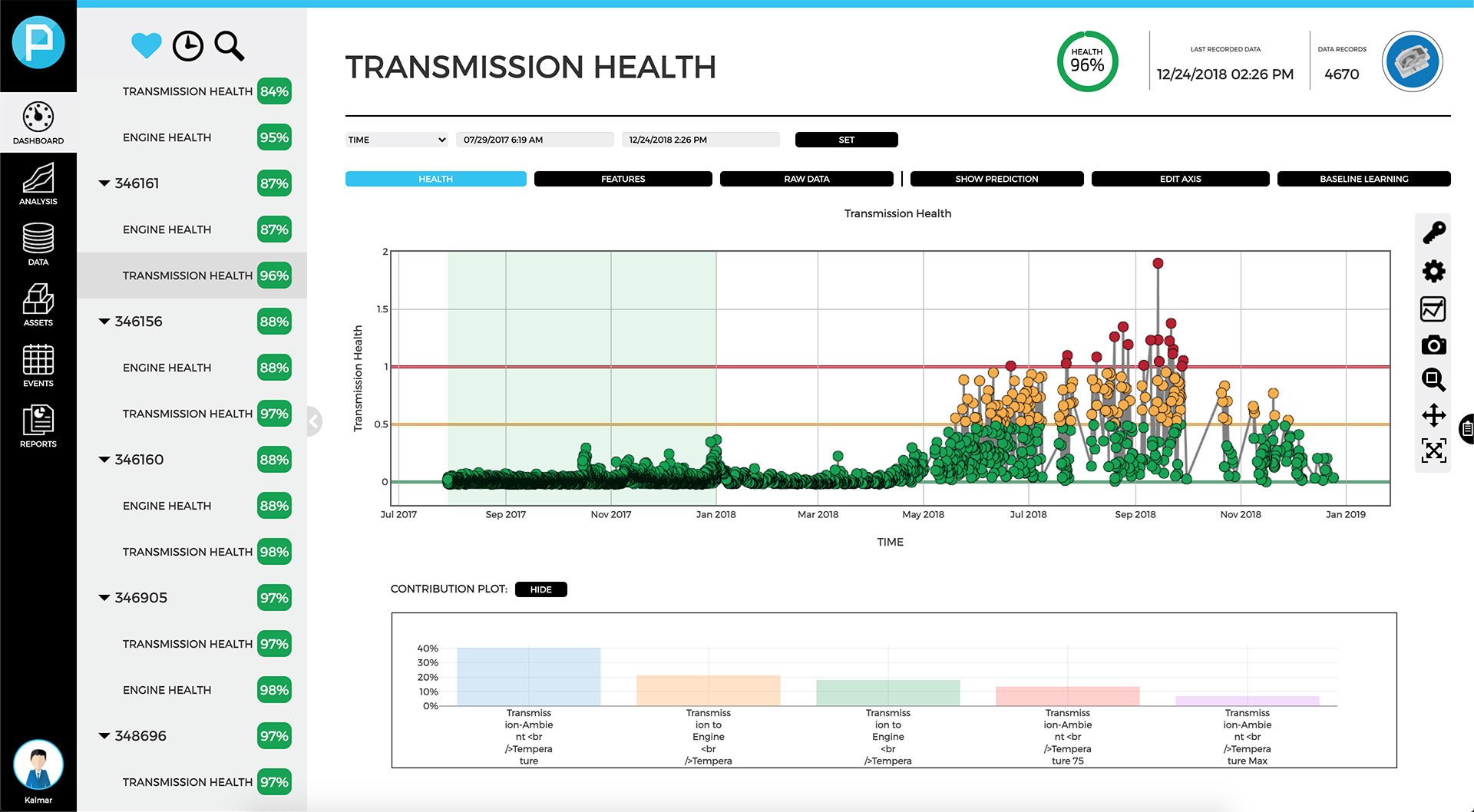

Predictronics developed a predictive maintenance solution, powered by our PDX software, for a customer in the cargo handling industry. This solution provides accurate detection of anomalous behavior in the engine and transmission of terminal tractors.

When deployed, this solution can provide an early warning of impending issues and deliver the information needed for personnel to take action in order to prevent failures, schedule maintenance, and ensure fleet availability.

Value

Out-of-service freight trucks can cost a company fleet $850 - $1000 per day in component repairs, labor, and towing services alone. Predictronics’ predictive solutions can help trucking companies eliminate unplanned downtime, extend component life, reduce failures, prioritize vehicles in need of service, and prevent unexpected delays. This reduces lost profits and the need for spare truck rentals, lowers insurance premiums, increases vehicle availability and safety, and improves on-time performance and fuel economy.

With experience in monitoring and diagnosing failure in diesel engines and electric rail, the Predictronics team can create predictive maintenance solutions to help those in the trucking and railway industries prioritize their maintenance schedule, not only saving them repair and labor costs, but also lost profits due to delayed shipments. View Part II of our Cargo and Freight Industry Series: Sea.