LAUNCH: FACTORY SENTINEL FOR INDUSTRIAL ROBOTS

APRIL 9, 2018

Industrial robots are the backbone of manufacturing. In factory floors across the globe, they work to assemble goods that are essential to modern society, including automobiles, electronics and airplanes.

Because the world relies so heavily on this industry, there is little to no space for unexpected failures that impact productivity. Hence, Predictronics is pleased to introduce Factory Sentinel for Industrial Robots, a ready-to-deploy, scalable solution to analyze, visualize and monitor robot health.

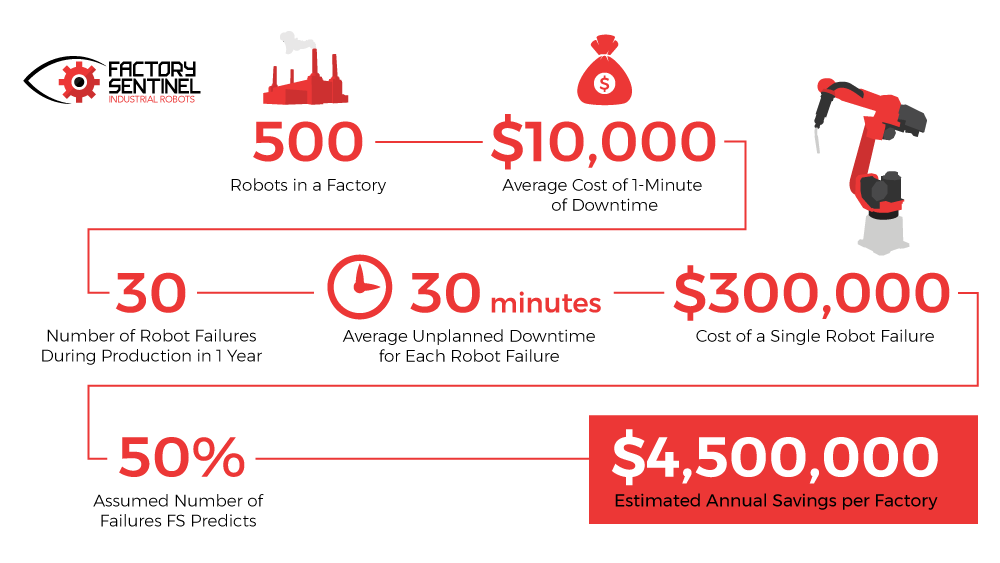

In manufacturing, robot failures are responsible for the loss of hundreds of thousands of dollars in unplanned downtime. With Factory Sentinel for Industrial Robots, faults that result in production line bottlenecks, poor product quality and scrap can finally become a thing of the past.

The solutions’ main differentiator is that it uses different variables, such as torque, vibration and temperature data, to deliver accurate health predictions before failures occur. Its pre-built algorithm requires no prior data science experience, and its visualization tools are compatible with most electronic devices, making it accessible to factory personnel on the shop floor.

The solution is also compatible with multiple robots. “We wanted to create an application that could work for most robots, since factories use different makes and models in their facilities,” says Predictronics Data Scientist Matthew Buzza. “It is not efficient to have a different solution for each robot.”

Factory Sentinel for Industrial Robots translates Predictronics’ years of expertise in developing industrial predictive technologies into a single, off-the-shelf solution. Officially launched April 9, the software was first developed to predict failures in an automotive manufacturer’s welding robots.

After the solution successfully predicted an impeding failure, it was further developed by a team of highly skilled data scientists and engineers to include more advanced health visualization tools.

Combined, these features allow for a predictive strategy that is proactive rather than reactive. Failures that once meant significant monetary losses become easily predictable, enabling personnel to plan for corrective actions that ensure productivity is maintained throughout the factory.

“Our experience developing predictive solutions for the manufacturing segment, especially for the automotive industry, enabled us to create a solution that is accurate as well as user-friendly,” says Predictronics CEO Edzel Lapira. “With Factory Sentinel, anyone can make educated decisions that improve overall productivity and increase profitability.”

Factory Sentinel for Industrial Robots is the first vertical application of the Factory Sentinel suite. In the future, Predictronics hopes to develop more off-the-shelf applications to address failures in regularly used equipment such as motors, bearings, wind turbines, rotating machinery, etc.

For more information and weekly updates, follow Predictronics:

Monitor your industrial robots today!

REQUEST A DEMO