The Predictronics Process for Industrial Solutions

One minute of downtime can cost tens of thousands of dollars. In the age of digital transformation, companies cannot fall behind their competitors when it comes to investing in technologies that impact productivity and profitability. Predictronics’ solutions demystify industrial big data to give companies actionable insights, ultimately eliminating downtime and improving product quality for a worry-free industrial process.

1

Introduction

ONE TO TWO HOURS

ACTIONS

Introduction to Predictronics

Overview of Predictronics' products and services

Customer discusses challenges, opportunities, goals and requirements.

OUTCOMES

Determine future tasks and schedule follow-up visit

Identify use cases relevant to identified challenges

Customer prepares list of critical assets, corresponding components and other relevant information

2

Workshop

ONE DAY

ACTIONS

Customer shop floor tour

In-depth PDX solution and use case presentation

Customer presents criticality analysis and expectations

Technical discussion with customer stakeholders

OUTCOMES

Determine technical specifications of proposed solution based on target critical asset(s) and customer requirements

Provide proposal for proof-of-value pilot project in two weeks

3

Proof of Value

THREE TO SIX MONTHS

ACTIONS

Develop pilot project that results in a replicable solution

Configure and implement pilot project solution

Pilot cost based on configuration service only — free trial of Predictronics software

OUTCOMES

Standardized value assessment

Deliver proposal, quote and master service agreement (MSA) for broader implementation

Solutions

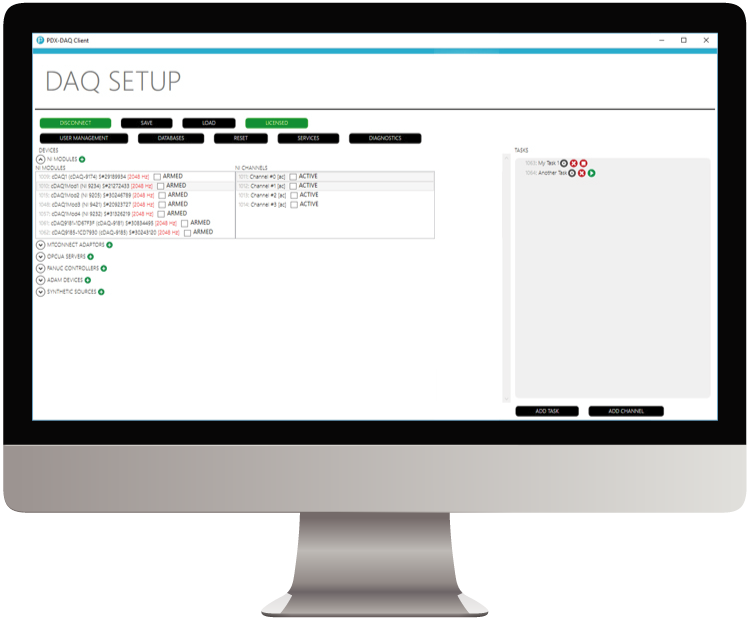

The first step to harnessing the full power of an industrial process is collecting data. PDX DAQ is a software application that allows users to synchronize data collection from multiple sources for any given period of time. The result is an intentional and effective data acquisition approach, which only yields the necessary information for analysis and producing real-time, impactful results.

Don’t have a data collection strategy in place yet? Our team of experienced automation engineers and data scientists can help with the right data acquisition plan for your company’s needs.

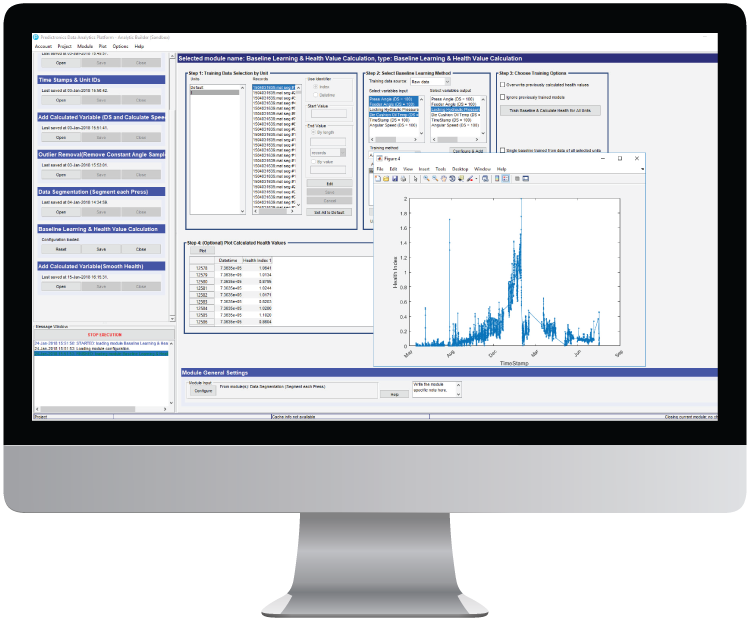

Simply collecting data is not enough – further analysis is needed to draw useful meaning from it. PDX Sandbox is a software for developing custom applications, analyzing data and predicting impending failures.

Built upon extensive domain knowledge and equipped with algorithms that facilitate model-building, PDX Sandbox is a deployable, scalable and intelligent solution that enables users to analyze data without having to become an expert. Predictronics can provide training, pre-configured models and tutorials to get users started on creating and customizing solutions.

Accessible, understandable and actionable information enables proactive decision making. PDX Deploy is an intuitive data visualization application that manages and monitors critical assets, issues detailed reports, maps degradation trends and predicts potential failures to achieve worry-free uptime.

Already have an asset management system in place? Customers can still harness the power of PDX Deploy’s unique functions through an API that is compatible with most data analysis platforms.

CONSULTING

Predictronics is uniquely suited to deliver predictive solutions for industrial applications by possessing the right combination of domain knowledge, industry experience, and data science and programming skills. Our team helps companies deploy accurate solutions that improve and optimize business operations.

Set up a meeting today with our expert data scientists and engineers. From just one consultation, let them develop a solution that is right for you with our proof-of-concept process. We can pinpoint your areas of need to create a predictive solution that ensures effective and impactful results, improving your machine maintenance schedule, enhancing production efficiency, boosting product quality, and saving you time, money and resources.

Data Acquisition & Automation Services

Not all data is useful: Predictronics can help you collect the right data, at the right time, or craft a full data acquisition plan so customers can collect information that drives real-time, impactful results.

Health Monitoring

Machine health information provides critical insights that drive proactive decision making. Predictronics’ monitors assets to determine their health value and how quickly potential problems are escalating.

Fault Diagnosis

The key to efficient problem-solving is accuracy. Predictronics uses data to determine the root cause of your production problem, saving time and money on troubleshooting and unnecessary repairs.

Lifetime Prediction

Utilizing a machine to its fullest capacity while still avoiding failures during production is crucial to any process. Predictronics monitors machine health to predict exactly when your equipment will need maintenance.

Product Quality Prediction

The goal of any organization is to reduce waste while maintaining the highest possible product quality. Predictronics monitors machine health to minimize testing and ensure quality standards are met.

Industrial AI

Predictronics has expertise in Industrial AI through the application of artificial intelligence and machine learning to address gaps in industry in the areas of customer value creation, productivity improvement, and insight discovery.

Factory Sentinel for Industrial Robots is an off-the-shelf, rapidly deployable data visualization and analysis application for industrial robots that enables users to monitor robot health without any prior data science experience.

This solution also works with countless different makes and models of robots and alerts factory personnel to the source of the robot failure before it occurs, providing businesses with the opportunity to schedule preventative maintenance. Proactive decision-making through predictive analytics ensures worry-free uptime, cost savings and increased profitability.